Low Cost Mechanically Robust Silica Aerogel Technology

Web Published:

11/18/2020

A low-cost mechanically robust silica aerogel technology enhances fiber-based building insulation R-value performance, soundproofing, thermal barrier textiles fabrics, ceramic foams, papers and composites thereof.

Energy efficiency in buildings, aerospace, extreme environments and many other sectors seek low cost, scalable, lightweight and mechanically strong superinsulation materials (thermal and acoustic). Superinsulation aerogels are one of the most efficient thermal insulation materials. Large-scale utilizations of aerogel have been prohibitive due to its complex supercritical drying process which avoids the capillary induced structural degradation during the drying. This invention uses sol-gel chemistry coupled with ambient pressure drying that significantly reduces cost, processing time and energy input for producing aerogel foams with pore size below 10nm as well as enabling foam-fiber composites including flexible thermal insulating papers, sheets and embedded functional textiles.

University at Buffalo researchers have developed methods of making ceramic foam and foam-fiber composites using low cost sol-gel chemistry based on in-situ generation of a pore-forming gas and reaction of the precursor(s) which occur at ambient pressures or in sealed environments. The process can integrate fibers of various types including, for example, traditional ceramic insulation fibers or a wise variety of textiles and natural fibers, imparting the aerogel benefits to the added fibers. The novel invention eliminates the prior art of complex aerogel processing and VOC solvents involved in producing ceramic foams by conventional high-pressure super critical drying. Methods for making the material transparent have also been demonstrated.

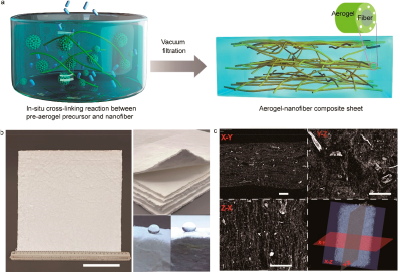

Figure 1. (a) Schematic illustration of the manufacturing process of C-FRAero with two main steps: (1) in situ cross-linking reaction of preaerogel precursor (HCl, CTAB micelles, urea, and sodium silicate) and nanofibers; (2) C-FRAero paper sheet via vacuum filtration. (b) Demonstration of C-FRAero sponge sheet with the scale bar 10 cm, and the inset bottom images showing the hydrophobic capability after in situ trichlorosilane surface coating. (c) X-ray computed tomography (CT) scan images of C-FRAero sheet 3d bulk. X−Y and Y−Z plane CT images show the nanofiber layer stacks of the sample. The Y−Z plane CT image shows the fiber-aerogel morphology of the layer.

Figure 1. (a) Schematic illustration of the manufacturing process of C-FRAero with two main steps: (1) in situ cross-linking reaction of preaerogel precursor (HCl, CTAB micelles, urea, and sodium silicate) and nanofibers; (2) C-FRAero paper sheet via vacuum filtration. (b) Demonstration of C-FRAero sponge sheet with the scale bar 10 cm, and the inset bottom images showing the hydrophobic capability after in situ trichlorosilane surface coating. (c) X-ray computed tomography (CT) scan images of C-FRAero sheet 3d bulk. X−Y and Y−Z plane CT images show the nanofiber layer stacks of the sample. The Y−Z plane CT image shows the fiber-aerogel morphology of the layer.

- Low cost (>90%) method that enables scalable, roll-to-roll processes

- Superior thermal and acoustic insulation and fire-resistant performance - thermal conductivity as low as 0.0190 W m-1 K-1 and high mechanical integrity of the compressive strength of 100.56 MPa, enabling shape customization

- Exceptional soundproof properties (sound reduction by 28.3%, or 22.3 db at a thickness of 15 mm at frequency of 2000 Hz) vs. reference insulating foam

- Does not require the complex processing, VOC solvents or conventional high-pressure super critical drying

- Significantly increases the R-value of insulating fibers, foams, papers and textile materials such as nylon, polyaramid or cellulose

- The highly insulating aerogel ceramic foam can also be made transparent.

Applications:

- Superinsulation for commercial and residential buildings, aerospace, and extreme environments

- Flexible textile fabrics with high insulation properties - extreme cold or extreme heat, protective outerwear for fire fighters and extreme temperature industrial applications

- High efficiency acoustic soundproofing materials

- High temperature, extreme temperature insulation wraps, blankets, sheets and papers

Intellectual Property Summary:

Provisional patent application 62/791,778 filed 1/12/19; PCT/US2020/13409

Stage of Development:

- Demonstration of process and sample materials in various forms including bulk, powder, paper, sheet, foam, fiber impregnated, textile/fabric composite, commercial building insulation composite

Licensing Status:

Available for licensing.

Nano Letters 2020 20 (2), 1110-1116

Nano Letters 2020 20 (5), 3828-3835

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|